Our products

Conveyor Technology

For efficient production processes and logistics.

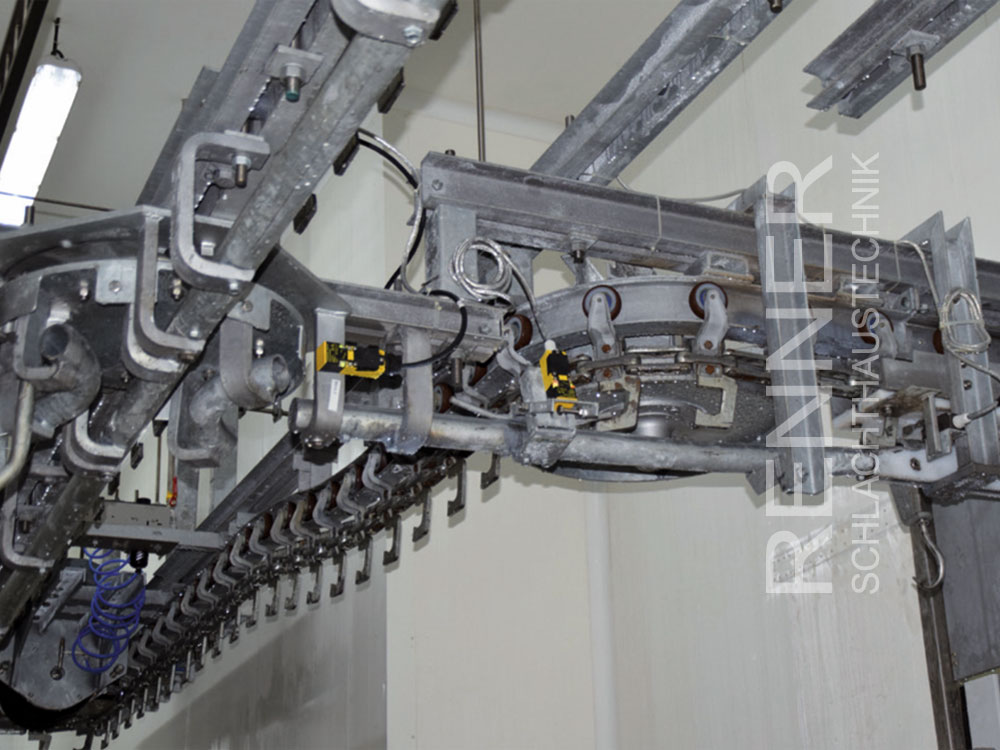

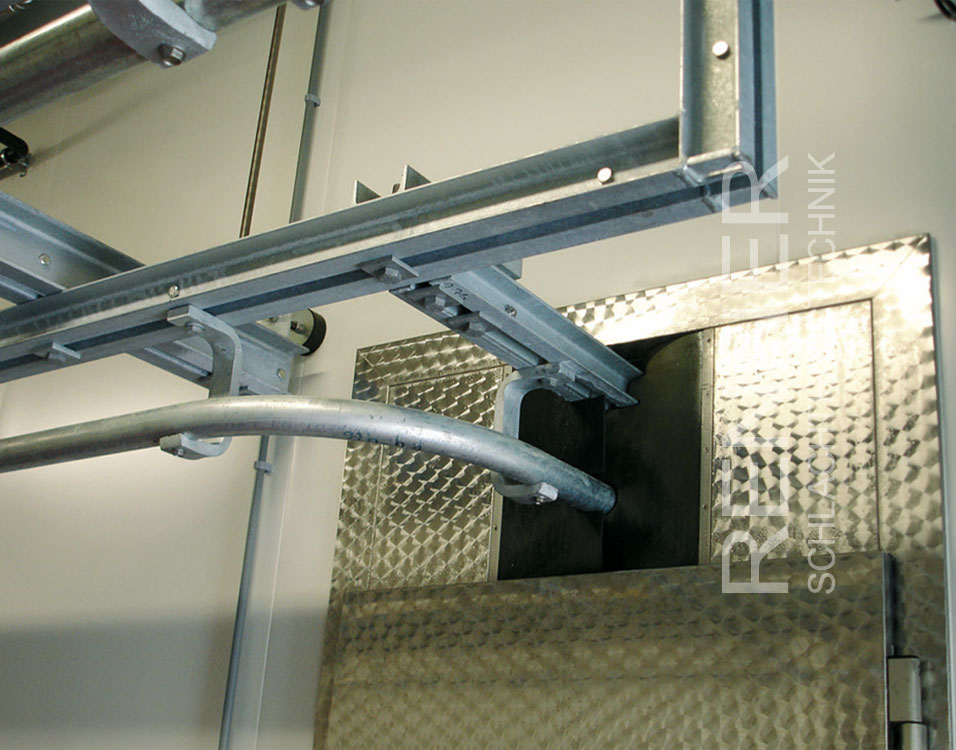

Utmost reliability is essential when it comes to conveyor technology in slaughterhouses und and boning plants. It determines how smooth and efficient your slaughter process line will function. An outage at one station means that the entire line comes to a standstill. We therefore strive for zero outage times by applying the newest technological standards and Made in Germany quality.

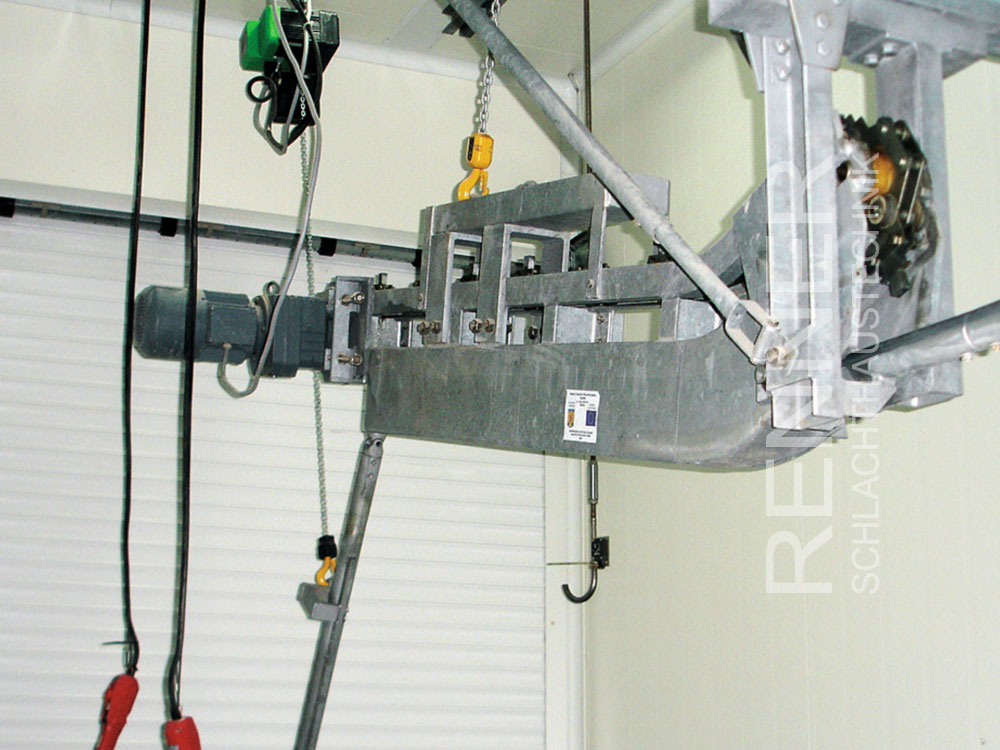

RENNER Schlachthaustechnik analyses, constructs, manufactures and installs slaughter conveyors and conveyor facilities for cattle, pigs and sheep. On an international scale, these are specifically tailored to each of your respective slaughter process lines and are suitable for all demands.

The complete conveyor systems portfolio.

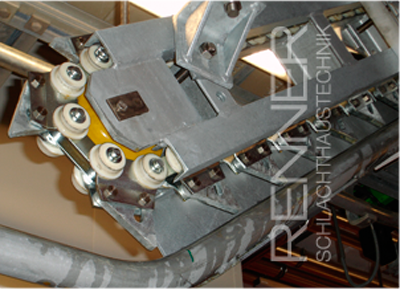

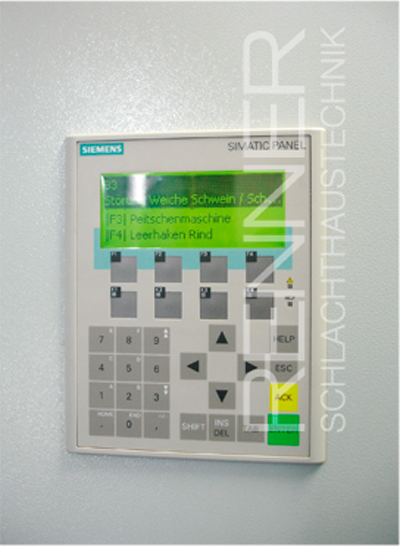

We deliver all kinds of conveyors and transport belts to your doorstep: ranging from apron conveyors and belt conveyors to chain conveyors, stack conveyors and conveyors for bowls through to pneumatic or hydraulic push rod conveyors. The chain hoists, winches and switches – for example rotating track switches, cross-track switches and pneumatic sliding track switches – round off our offer. The most modern PLC systems also enable optimal control of your facility.

Lieferprogramm

- slaughter conveyors for cattle, pigs and sheep

- cooler conveyors

- conveying systems for fast cooling

- conveyors with scales

- conveyors for bowls

- organ conveyors

- loading elevators

- cattle loading elevators

- winches

- chain hoists

- pneumatic or hydraulic push rod

- conveyors

- multiflex chain conveyors

- belt conveyors

- conveyor belts for skin, offal and bones

- pneum. transport systems for waste disposal

- vacuum exhaust units

- empty hook conveyors

- empty hook elevators

- empty hook stack conveyors

- empty hook cleaning

- conveying and handling systems for cattle hides

- tubular track, galvanised and/or with plastic inlay

- pneumatic sliding track switches

- rotating track switches

- cross track switches

- telescopic loading tracks

- automatic greasing of tubular tracks