Our Products

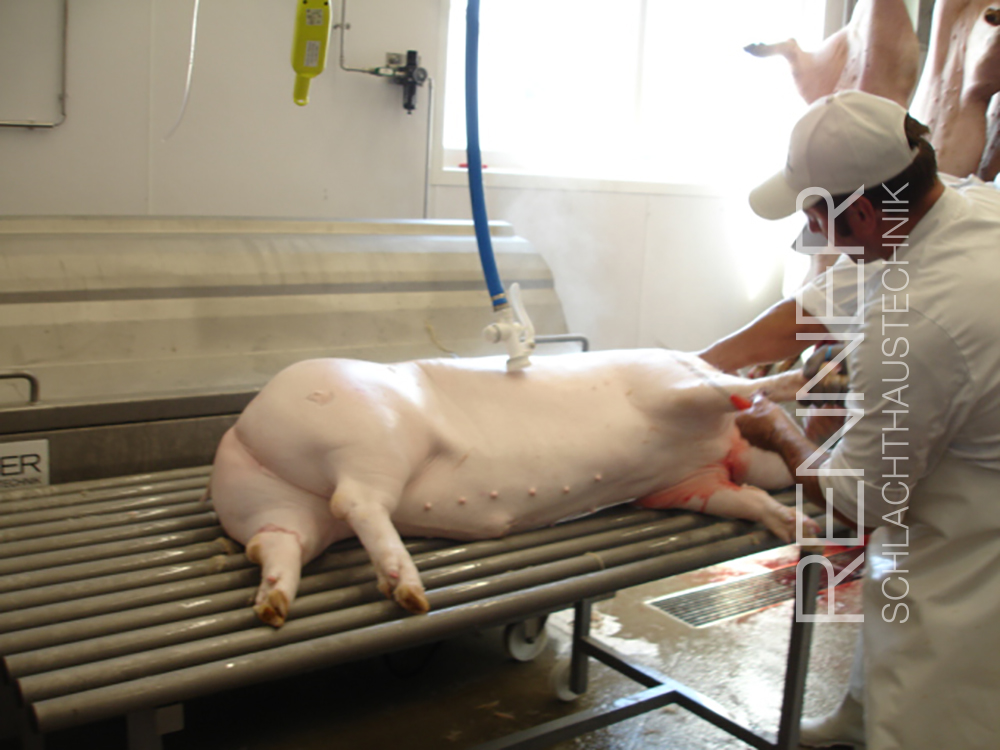

Pig Slaughtering

Made in Germany.

Giving you an international head start

Different factors influence the slaughtering of pigs. The market as well as clients require economical, hygienic and transparent processes. At the same time, animal-friendly slaughtering is increasingly in the spotlight. The most modern technology is the solution to master the balancing act between economic viability and animal welfare.

RENNER Schlachthaustechnik develops pig slaughtering systems – from complete systems and entire facilities to the individual products that cater for the very specific needs of a butchery. Everything is tailored to your needs, everything you need to give you a competitive edge. The systems are designed for capacities of a maximum of 240 pigs per hour.

The complete program along the entire slaughter process line

No matter if it is for industrial slaughterhouses and boning plants or the artisan butchery with the smallest of spaces: RENNER Schlachthaustechnik offers you everything that you may need for pig slaughtering. Starting at the planning stage and ending with a slaughter process line designed and implemented entirely for you.

PRODUCT RANGE

- animal welfare-compliant lairages

- races

- CO2 stunning

- electrical stunning

- horizontal bleeding

- vertical bleeding

- bleeding channels

- blood collecting systems

- blood pumps

- bleeding conveyors

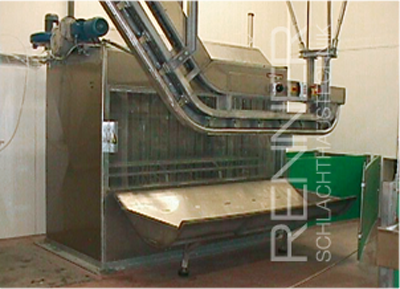

- scalding systems, horizontal and vertical

- de-hairing machines

- de-hairing and singeing machines

- drying whips

- furnaces, natural gas or liquified petroleum gas

- brushing machines

- polishing machines

- hygienic dressing platforms

- slaughter conveyors

- organ conveyors

- laboratory equipment for checking for trichinae

- pneumatic work platforms

- gut cleaning machines

- stomach cleaning machines

- scalding and de-hairing machines for sucking pigs

- splitting saws

- rectum cutter

- paw pincers

- vacuum extraction units